Importance of O-Ring Seals and O-Ring Calculator

In the time of industrial innovations, our attention often gravitates toward complex systems like high-tech controls and the latest circuits. Although these things and intricate gears are imperative, the success and productive growth of the industry often depend on simple elements like O-rings. Therefore, O-ring seal suppliers must provide customers with custom sizes and durable products. In this blog, we see the importance of O-rings for various industrial uses. It also explains the importance of the O-ring calculator.

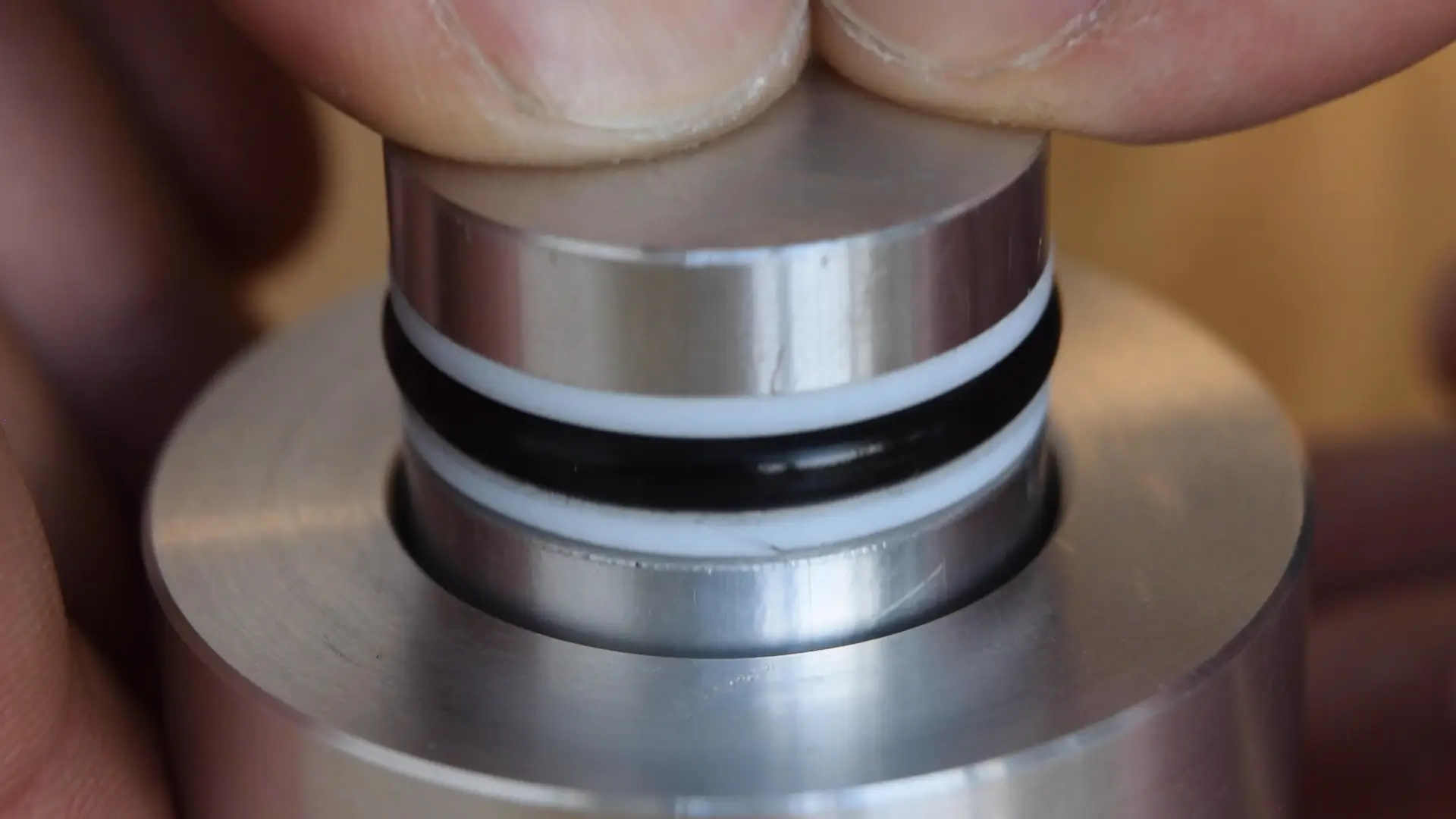

Advantages of O-Ring Seals

The stunning benefits of using O-rings make them an essential part of different industrial applications. Let’s see the advantages of O-rings, which you must know.

- Suitable option for various motion modes, axial reporting, combined motion, and rotary motions as well.

- Ideal choice of different sealing forms like dynamic and static sealing.

- Available in a simple design and compact structure for convenient utilization.

- A stunning option for distinctive materials with grooves and strong and standardized dimensions.

- Use for various sealing media: oil, water, gas, and chemical media.

- Selecting suitable rubber materials and proper formula design.

- Installation and replacement of rings is easy.

Material Possibilities As O-Ring Elastomer

Suppliers and manufacturers choose the perfect elastomers for sealing applications. They use a compound comprised of a polymer, fillers, and a cross-linking system with additional ingredients to obtain the perfect manufacturing and application needs.

The basic design of O-rings starts from selecting the polymer and is reinforced with additional agents like colored pigments, carbon block, curing, and vulcanizing. Seal company also uses plasticizers, accelerators, and antioxidants for this procedure. Here is the list of possible materials or elastomers that are chosen according to the purpose in mind.

- Acrylonitrile butadiene, Nitrile, or Buna N

- Polyurethane rubber

- Silicone rubber

- Fluorocarbon rubber

- Perfluorocarbon

- Fluorosilicone

- Hydrogenated Nitrile

- Ethylene Propylene

Role of O-ring Calculator

After learning the materials and elastomers, it is now essential to understand the worth of using an O-ring calculator and its benefits for precision results; it is a mandatory tool for maintaining and designing systems that depend on O-shaped rings. The use of this calculator makes the correct O-rings selection procedure easier by explaining the cross-sectional dimensions, materials, and sizes. Besides, this information ensures proper optimal performance to meet needs.

If you select the wrong size and materials, it leads to equipment failure, leaks, and costly repairs. For this purpose, the O-rings calculator explains all information accurately according to inner and outer diameters, compression, and groove dimensions, which is necessary for fabulous sealing purposes.

The O-ring size calculator provides perfect recommendations for O-seal sizes and tolerance levels, just inputting basic information about dimensions and applications. Here are some benefits of using this calculator to get recommendations for O-seals and rings.

- Improved system efficiency and longevity

- Reduce the risk of sealing failures

- Saves time in choosing the ideal size

- Enhance reliability

O-seal calculators are an easy-to-use tool that assists you in doing the job on the first attempt. Additionally, the primary consideration when choosing the right O-ring according to the use is compression and intention ratio. So, pick them wisely and accurately to meet the purpose. Bay Seal Company also has an O-ring calculator, which allows you to calculate size, dimensions, and other aspects.

O-Rings Usages

O-rings can used in extensive industries for various applications. It is a simple component yet is imperative in industrial manufacturing. Professionals use this seal in hydraulic, pneumatic, vacuum systems, and medical devices. Despite this, the perks of this seal have an effective role in the oil industry, as well as the automotive and aerospace fields. Let’s see the importance and consumption of these seals in various industries.

Plumbing and Water Systems

In plumbing and water systems, the O-ring seal’s role is insane. Whether you install plumbing supplies for in-home corporate or industrial use, O-seal is required to ensure the blockage of leaks sealing. Apart from this, they are resistant to temperature, chemicals, and instability, which makes them perfect for any application.

Food and Beverages Industry

Experts and engineers use O-rings in packaging machinery and food processing equipment to confirm perfect sealing. They ensure watertight and airtight sealing in these industries. O-seals protect from leaks and contamination. Furthermore, silicone and EPDM-based O-rings meet the FDA standards, which is why food and beverage companies use these O-rings.

O-Rings Seals Application in the Oil and Gas Industry

O-rings are imperative in sealing systems with harsh temperatures and high pressure. Indeed, this includes valves, pipelines, pumps, and drilling devices that need efficient ceilings. In the gas and oil industries, durable O-rings are preferred to prevent leakage and provide excellent sealing. In addition, O-rings have high resistance to heat, corrosion, and chemicals.

Effective Element in the Aerospace and Automotive Industry

Engineers use these rings to fulfill various purposes, such as O-rings for landing gear, fuel pumps, and hydraulic systems. They can also use them in engines. Besides, these seals can withstand pressure instability and harsh atmosphere conditions. Thus, they confirm the safety and reliability of spacecraft and aircraft.

O-rings play a pivotal significance in automotive elements as well. In this industry, these seals can be used for breakers, fuel stems, transmissions, and air conditioning. O-seals prevent oil, fuel, and air leaks to ensure the vehicle operates effectively and safely. Also, mechanics and engineers use them in fuel injectors, radiators, and engine gaskets.

Prevent Chemical Leakage

O-rings and seals protect valves, joints, and pipes, which ensure the transportation of chemicals in the industry. These seals are fabricated with high-quality elastomers that ensure the protection of chemicals and fluids in the transferring process. However, you are required to calculate the right size as per the materials before buying them.

Final Words

Above blog explains the importance of O-ring seals and their calculator. The use of this tiniest and most crucial part has many benefits for various reasons. For instance, it is utilized for plumbing, vacuum sealing, the food and beverage industry, etc. Moreover, it explains the benefits of the O-ring calculator as well. This calculator saves time and equipment failures and maximizes reliability as well.